ABES assemCon

Geometry control during segmental bridge construction

- On-site survey + stage-by-stage model

- Geometry forecast

- Shimming optimisation

ABES assemCon

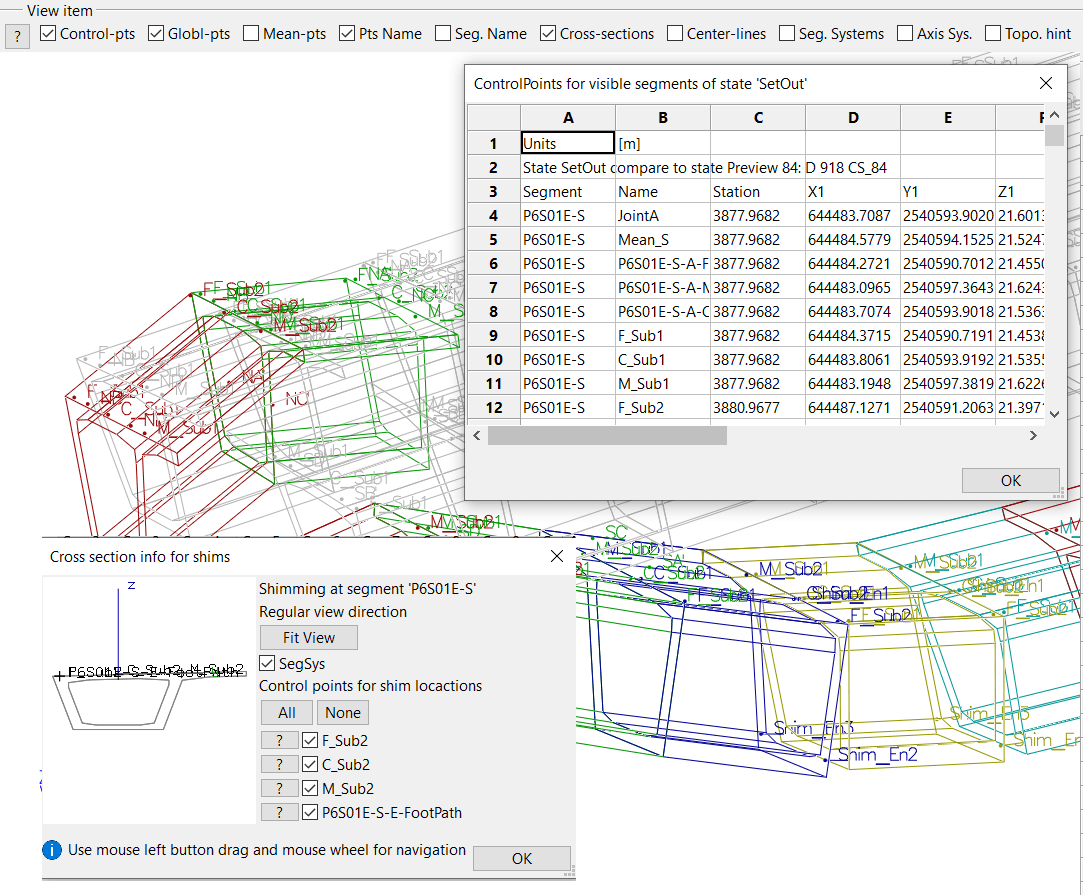

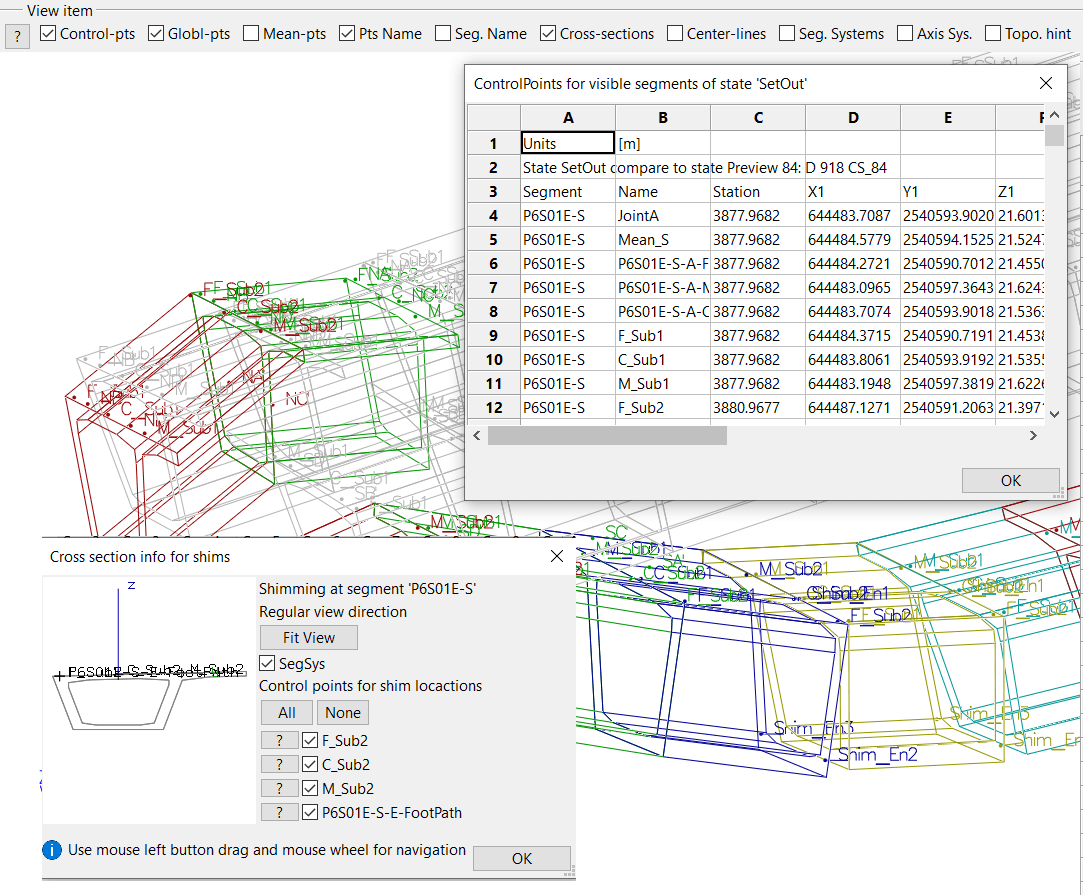

Superior geometry forecasts, setting-out data, shimming optimisation, and quality control during segmental bridge construction. ABES assemCon combines a detailed stage-by-stage model with survey data from the construction site.

General Functions

- On-site setting out data

- Geometry forecasting during construction

- Ongoing cross-checks with target points throughout construction

- Simulation and optimisation of corrective measures - e.g. shimming

- Accurate consideration of as-cast geometry, on-site survey data, and construction stage deflections

- Quality assurance through error tracking and error analysis functions

- Record of construction history and final as-built geometr

Optimised As-Built Geometry

- Optimised setting-out data for starter segments

- Accounting for casting imperfections introduced in the casting yard

- Tracking and adapting to on-site survey data

- Consideration of construction stage deflections

- Geometry forecasts throughout construction

- Optimisation of shimming strategies

- Documentation and quality control

Adaptability

- Balanced cantilevers, span-by-span, any other construction method

- Bridge girders, pylons, inclined members

- Interfaces to CAD packages, spreadsheet programs, and word processing software